Our Company Today

Faribault Foods and Arizona Canning Company combined in 2014 under our parent company, La Costeña USA. Today, Faribault Foods and Arizona Canning Company operate as a unified company under the name Faribault Foods, offering an extensive portfolio of premium food products. Our multiple locations enable us to source the best ingredients and transport our products more efficiently.

Our Vision

Our vision is to be a leading, high-quality food company that provides the greatest customer satisfaction through products and services based on the development of highly skilled, committed personnel and the use of cutting edge technology to create new products.Our Values

Respect • Integrity • Honesty • Equity & Justice • Loyalty • Responsibility

Our History

1888

Faribault Canning & Preserving Company is incorporated by local Faribault investors. Unfortunately, in the first several years, the fledgling company lacks strong leadership, financing and proper equipment.

Faribault Canning & Preserving Company is incorporated by local Faribault investors. Unfortunately, in the first several years, the fledgling company lacks strong leadership, financing and proper equipment.

1895

Ten local farmers buy-out the struggling original investors and re-incorporate as Faribault Canning Company. By 1990, an average of 350,000 cans of corn are packed per season.

Ten local farmers buy-out the struggling original investors and re-incorporate as Faribault Canning Company. By 1990, an average of 350,000 cans of corn are packed per season.

1903

Faribault Canning Company expands their facility, doubling capacity to an expected output of 1.5 million cans. But a fire in 1904 burns the factory down, and the owners scramble to get new equipment in time for the year's corn pack.

Faribault Canning Company expands their facility, doubling capacity to an expected output of 1.5 million cans. But a fire in 1904 burns the factory down, and the owners scramble to get new equipment in time for the year's corn pack.

1916

Faribault Canning Company is bought by the Douthitt family, and in 1917 part ownership is sold to food broker Charles Vandever. Douthitts continue to manage the operations.

Faribault Canning Company is bought by the Douthitt family, and in 1917 part ownership is sold to food broker Charles Vandever. Douthitts continue to manage the operations.

1923

La Costeña was founded in Mexico by Don Vicente López Resines. After purchasing a convenience store called La Costeña, he began producing Serrano and largo chilies in vinegar in glass jars and sold them under the same name.

La Costeña was founded in Mexico by Don Vicente López Resines. After purchasing a convenience store called La Costeña, he began producing Serrano and largo chilies in vinegar in glass jars and sold them under the same name.

1932

Albert Vandever (son of Charles) becomes President of Faribault Canning Company, eventually buys 100% ownership, and guides the company through depression, dust bowl & WWII.

Albert Vandever (son of Charles) becomes President of Faribault Canning Company, eventually buys 100% ownership, and guides the company through depression, dust bowl & WWII.

1937

La Costeña begins self-manufacturing cans.

La Costeña begins self-manufacturing cans.

1940

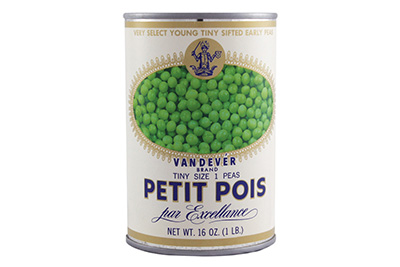

Faribault Canning Company introduces pea production, specializing in Vandever brand Petit Pois.

Faribault Canning Company introduces pea production, specializing in Vandever brand Petit Pois.

1943–1945

Faribault Canning Company is commissioned as German Prisoner of war camp by the US government.

Faribault Canning Company is commissioned as German Prisoner of war camp by the US government.

1947

Edmund MacDonald (son-in-law of Albert Vandever) joins Faribault Canning Company's Board of Directors.

Edmund MacDonald (son-in-law of Albert Vandever) joins Faribault Canning Company's Board of Directors.

1948

La Costeña opened the first production plant in Mexico City with an area of 5,000 square meters (53,820 sq ft).

La Costeña opened the first production plant in Mexico City with an area of 5,000 square meters (53,820 sq ft).

1950

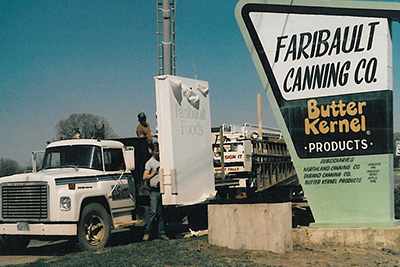

Faribault Foods acquires 50% interest in the Butter Kernel brand. New semi-automated corn huskers and cutters are installed, boosting production.

Faribault Foods acquires 50% interest in the Butter Kernel brand. New semi-automated corn huskers and cutters are installed, boosting production.

1951

La Costeña attained its first automatic production line to manufacture 3-kilogram cans. Soon after, it expanded automatic production with a 105-gram can line.

La Costeña attained its first automatic production line to manufacture 3-kilogram cans. Soon after, it expanded automatic production with a 105-gram can line.

1968

La Costeña expands their facility to 180,000 square meters (1,938,000 sq ft). Only 10% is used for production at the time, and the remainder built for future expansions needs.

La Costeña expands their facility to 180,000 square meters (1,938,000 sq ft). Only 10% is used for production at the time, and the remainder built for future expansions needs.

1969

Faribault Foods purchases Northland Canning in Cokato, MN.

Faribault Foods purchases Northland Canning in Cokato, MN.

1971

La Costeña relocates to a 250,000 square meter (2,691,000 square foot) facility in Tulpetlac, Mexico.

La Costeña relocates to a 250,000 square meter (2,691,000 square foot) facility in Tulpetlac, Mexico.

1972

Faribault Foods acquires remaining 50% of Butter Kernel brand and pitches to new accounts in new markets and products.

Faribault Foods acquires remaining 50% of Butter Kernel brand and pitches to new accounts in new markets and products.

1973

La Costeña establishes a relationship with the most important grocery chains in Mexico, securing significant market share.

La Costeña establishes a relationship with the most important grocery chains in Mexico, securing significant market share.

1975

La Costeña begins exporting chili peppers and sauces to the U.S.

La Costeña begins exporting chili peppers and sauces to the U.S.

1976

La Costeña starts production of tomato paste and olives

La Costeña starts production of tomato paste and olives

1977

Faribault Foods acquires Durand Canning Co. in Mondovi, WI and adds green and wax beans to Faribault's product line.

Faribault Foods acquires Durand Canning Co. in Mondovi, WI and adds green and wax beans to Faribault's product line.

1979

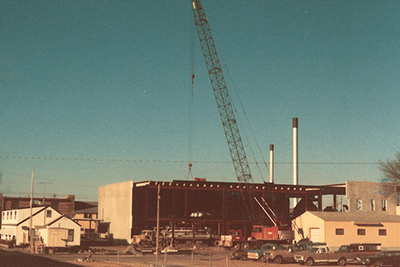

New plant constructed in Faribault, MN increases production and adds year-round production capability.

New plant constructed in Faribault, MN increases production and adds year-round production capability.

1983

Faribault Foods acquires the Kuner-Empson of Colorado Company, thereby acquiring the Kuner's brand (leading brand in the Rocky Mountains) and expanding product line to dry beans.

Faribault Foods acquires the Kuner-Empson of Colorado Company, thereby acquiring the Kuner's brand (leading brand in the Rocky Mountains) and expanding product line to dry beans.

1986

La Costeña introduces innovative can sealing technology that uses pressure sealing and eliminates the need for any external elements, thereby improving the recyclability of the cans.

La Costeña introduces innovative can sealing technology that uses pressure sealing and eliminates the need for any external elements, thereby improving the recyclability of the cans.

1987

Faribault Foods acquires Beaver Valley Canning company and its Mrs. Grimes brand. In 1988, Faribault Foods acquires Pride of Illinois vegetables from Pillsbury.

Faribault Foods acquires Beaver Valley Canning company and its Mrs. Grimes brand. In 1988, Faribault Foods acquires Pride of Illinois vegetables from Pillsbury.

1988

La Costeña brand begins development and positioning in the Mexican market with the start of its first advertising campaign.

La Costeña brand begins development and positioning in the Mexican market with the start of its first advertising campaign.

1990

New warehouse and packaging/distribution center are built at Industrial Park in Faribault, MN.

New warehouse and packaging/distribution center are built at Industrial Park in Faribault, MN.

1991

La Costeña's new production plant in Guasave, Mexico opens to produce tomato puree, vegetables and more.

La Costeña's new production plant in Guasave, Mexico opens to produce tomato puree, vegetables and more.

1994

Major expansion takes place at the Cokato, MN plant, and a new canned pasta production line for private labels begins at Faribault Foods.

Major expansion takes place at the Cokato, MN plant, and a new canned pasta production line for private labels begins at Faribault Foods.

1994

La Costeña launches its line of beans in the U.S.

La Costeña launches its line of beans in the U.S.

1997

La Costeña opens a new manufacturing plant in San Luis Potosi, Mexico that produces chiles, fruits and dry beans, making La Costeña the largest can foods manufacturer in Mexico. "Easy-open" can lids as well as new aseptic manufacturing methods are introduced.

La Costeña opens a new manufacturing plant in San Luis Potosi, Mexico that produces chiles, fruits and dry beans, making La Costeña the largest can foods manufacturer in Mexico. "Easy-open" can lids as well as new aseptic manufacturing methods are introduced.

1999

Faribault Foods acquires 50% of Shariann's organics and launches organic soup line at Cokato, MN.

Faribault Foods acquires 50% of Shariann's organics and launches organic soup line at Cokato, MN.

2000

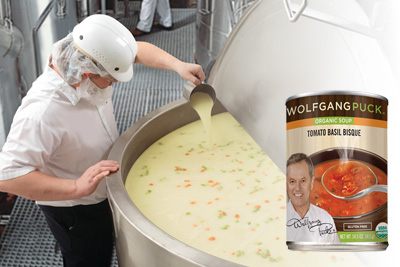

Faribault Foods begins producing Wolfgang Puck organic soups for Country Gourmet Foods, and becomes the largest producer of organic soups in the country.

Faribault Foods begins producing Wolfgang Puck organic soups for Country Gourmet Foods, and becomes the largest producer of organic soups in the country.

2000

La Costeña launches a new line of marinades, called Doña Chonita, featuring traditional Mexican flavors. A line of mayonnaise also launches.

La Costeña launches a new line of marinades, called Doña Chonita, featuring traditional Mexican flavors. A line of mayonnaise also launches.

2001

Faribault Foods acquires Sun Vista brand and creates Kuner's Southwestern line extension.

Faribault Foods acquires Sun Vista brand and creates Kuner's Southwestern line extension.

2002

Faribault Foods expands dry beans into baked bean production for Kuner's, Mrs. Grimes, and store-brand customers.

Faribault Foods expands dry beans into baked bean production for Kuner's, Mrs. Grimes, and store-brand customers.

2003

Faribault Foods shifts focus to year-round production of dry beans, pasta, soups, and chili. The company ceases vegetable production, with the exception of corn for Butter Kernel, Kuner's, and Pride.

Faribault Foods shifts focus to year-round production of dry beans, pasta, soups, and chili. The company ceases vegetable production, with the exception of corn for Butter Kernel, Kuner's, and Pride.

2003

La Costeña is certified ISO 9001

La Costeña is certified ISO 9001

2003

Faribault Foods acquires Chilli Man brand and production in Milnot, IL.

Faribault Foods acquires Chilli Man brand and production in Milnot, IL.

2005

Faribault Foods acquires juice pouch business from SoftPac Industries in Elk River, MN, and becomes leading private label in the category.

Faribault Foods acquires juice pouch business from SoftPac Industries in Elk River, MN, and becomes leading private label in the category.

2005

Construction of Automated Distribution Center begins in Ecatepec, Mexico, which opened in 2007. La Costeña obtains BRC Certification.

Construction of Automated Distribution Center begins in Ecatepec, Mexico, which opened in 2007. La Costeña obtains BRC Certification.

2006

La Costeña builds the village of Villa San Jose with the goal of giving their workers quality living conditions. The first school opens in 2008 and in 2010, a library, church, dining hall, tortilleria, grocery store are added.

La Costeña builds the village of Villa San Jose with the goal of giving their workers quality living conditions. The first school opens in 2008 and in 2010, a library, church, dining hall, tortilleria, grocery store are added.

2006

Faribault Foods acquires license to produce and market S&W Beans from Del Monte Foods.

Faribault Foods acquires license to produce and market S&W Beans from Del Monte Foods.

2006

La Costeña purchases the Slim Fast plant located in Tucson, Arizona, and established Arizona Canning Company.

La Costeña purchases the Slim Fast plant located in Tucson, Arizona, and established Arizona Canning Company.

2007

Arizona Canning Company acquires the Sun Vista brand of beans and sauces from Faribault Foods.

Arizona Canning Company acquires the Sun Vista brand of beans and sauces from Faribault Foods.

2010

Arizona Canning Company acquires Luck’s brand of beans, chicken and dumplings, and apples from ConAgra Foods.

Arizona Canning Company acquires Luck’s brand of beans, chicken and dumplings, and apples from ConAgra Foods.

2011

Faribault Foods acquires license for KC Masterpiece baked beans from Clorox and launches new Baked Bean items.

Faribault Foods acquires license for KC Masterpiece baked beans from Clorox and launches new Baked Bean items.

2013

Faribault Foods adds retort pouch capability to Cokato, MN facility.

Faribault Foods adds retort pouch capability to Cokato, MN facility.

2013

Arizona Canning acquires Kern's nectar brand from Stremicks Heritage Foods.

Arizona Canning acquires Kern's nectar brand from Stremicks Heritage Foods.

2014

Arizona Canning and Faribault Foods merge under La Costeña.

Arizona Canning and Faribault Foods merge under La Costeña.

2016

Construction begins on a new plant in Faribault, MN. The plant will include faster and more efficient production lines, as well as a can-making line. The expansion will increase the size of the entire complex to nearly 1 million square feet.

Construction begins on a new plant in Faribault, MN. The plant will include faster and more efficient production lines, as well as a can-making line. The expansion will increase the size of the entire complex to nearly 1 million square feet.

2016

Sold beverage manufacturing facility in Elk River, MN to Harvest Hill Beverage Company.

Sold beverage manufacturing facility in Elk River, MN to Harvest Hill Beverage Company.

2017

Completed construction and opened the manufacturing plant in Faribault, MN. The new facility combined three previously separate Faribault facilities into one operation, including can manufacturing, canning, labeling, storage and distribution.

Completed construction and opened the manufacturing plant in Faribault, MN. The new facility combined three previously separate Faribault facilities into one operation, including can manufacturing, canning, labeling, storage and distribution.

2019

As a leader in innovation, brought record-breaking number of new items to market, including over 15 new branded items, plus numerous custom-developed private label and co-manufactured items.

As a leader in innovation, brought record-breaking number of new items to market, including over 15 new branded items, plus numerous custom-developed private label and co-manufactured items.

Sustainability

As a family-owned business, sustainability has always been a core value for Faribault Foods. We are committed to supporting and enhancing the communities where we and our customers live and work. We continually invest in new and more efficient equipment to reduce water and energy usage in our plants and emphasize responsible waste disposal.